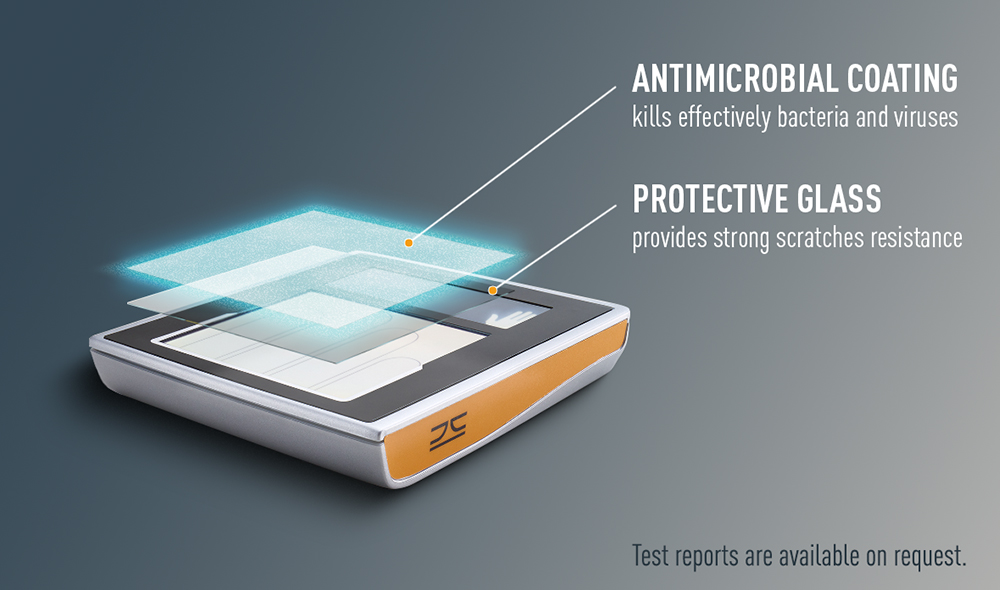

How does the antimicrobial coating work?

Antimicrobial Coating – Technical Specification

|

Fingerprint scanner |

Optionally availbale for LIVETOUCH QUATTRO, LIVETOUCH QUATTRO Compact |

|---|---|

|

Chemical basis |

Silicon dioxide matrix with integrated copper(I) oxide |

|

Transparency |

> 99 % |

|

Scratch resistance |

Antimicrobial coating tested for abrasion (according to to ISO 1518-1) |

|

Proof of Cleaning |

Antimicrobial Coating tested for Washability (according to ASTM D4213-92/D4828) |

|

Chemical Resistance |

Resistant to common fluids (cleaning agents, alcohol, lotions, etc.) |

|

Antimicrobial Effectiveness |

Both in the initial state and after the abrasion stresses investigated, the coating on glass showed significant antimicrobial activity and a germ reduction of 99.99%. (according to DIN ISO 22196) |

|

Temperature Stability |

-40 °C ... +90 °C (-40°F… 194 °F) |

|

Effectiveness |

Up to 3 years |